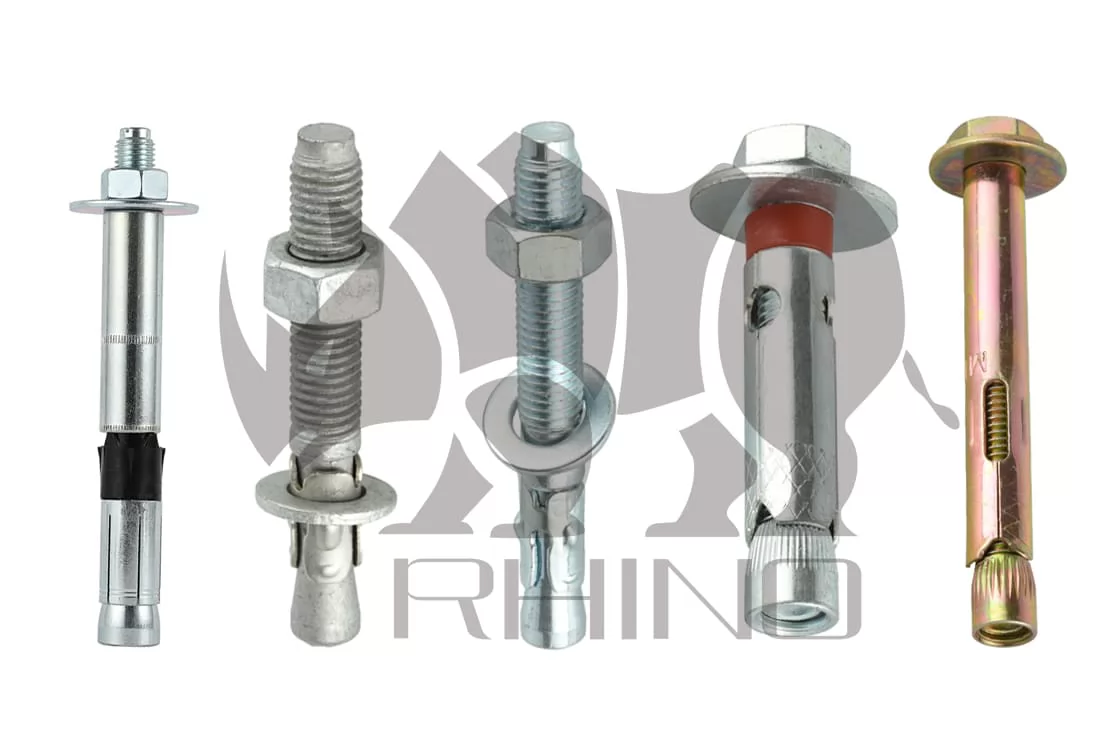

Anchors are fasteners used to fix structures or objects to substrates and are widely used in the fields of construction and engineering. Their main function is to ensure that objects are stable and immobile, and withstand tension, shear, and other external forces. Different types of anchors fix objects to substrates by expansion, chemical bonding, or mechanical locking. Choosing the right type of anchor depends on the specific application scenario and substrate type.

Structure and working principle:

Expansion Anchors: When the bolt is inserted into a pre-drilled hole and the nut is tightened, the expansion sleeve begins to expand, pressing against the wall of the hole, thereby providing mechanical locking force to secure the anchor in the substrate.

Chemical Anchors: Using chemical adhesives (such as epoxy resin) to fix the rod in concrete, brick walls, and substrates with large cracks, providing bonding strength through a chemical reaction.

Wedge Anchors: After the bolt is inserted into the pre-drilled hole, tightening the nut causes the metal expansion sleeve to expand, providing strong mechanical locking force.

Installation Steps:

Drilling the Hole: Drill an appropriately sized hole in the concrete surface. The diameter and depth of the hole are usually determined by the specifications of the anchor.

Cleaning the Hole: Clean the hole with a brush or air pump to ensure it is dust-free.

Inserting the Anchor: Insert the anchor into the clean, prepared hole.

Tightening the Nut: Use a torque wrench to tighten the nut, causing the expansion sleeve to expand and anchor securely against the walls of the hole.

We need to note when installing:

Ensure that the depth and diameter of the hole conform to the specifications of the anchor.

Wear appropriate safety gear during the drilling and installation process.

Tighten the nut using the recommended torque value to ensure optimal anchoring performance.

Heavy-duty anchors are fasteners specifically designed to withstand high loads, typically used in scenarios requiring extremely high fixation strength and safety. They are widely used in construction, bridges, large machinery, and infrastructure. The characteristics of heavy-duty anchors include:

Made of high-strength steel or stainless steel

Excellent tensile and shear strength

Designed for high-load environments

Typically have larger diameters and lengths to provide greater anchoring force and embedment depth.

| Characteristic | Heavy Anchor | Anchor |

|---|---|---|

| Applications | High load-bearing engineering projects | Securing light to medium loads |

| Design | Complex, with many extension mechanisms | Simple, suitable for general use |

| Material | High strength steel, stainless steel, alloy | Ordinary steel, plastic, zinc alloy |

| Performance | Excellent tensile strength, shear resistance and seismic resistance | Moderate load-bearing capacity and durability |

| Installation Requirements | Requires special tools and complex installation steps | Easy installation, no special tools required |

You can choose the most suitable anchor type according to different needs. Meigesi is your best choice. You can check the anchor or send a quotation directly to get relevant product information.

Established in 2010, Yuyao Meigesi Fastener specializes in the production and export of various fasteners, including screws, nuts, and bolts. As a professional nuts manufacturer, Meigesi exports products to over 50 countries across Eastern and Western Europe, and South America. With 13 years of experience, we have built a reputation based on professionalism, efficiency, and innovation, continuing to grow in the global fastener industry. If you have any needs for fastener products, you can always check our product list or contact us for a catalog.