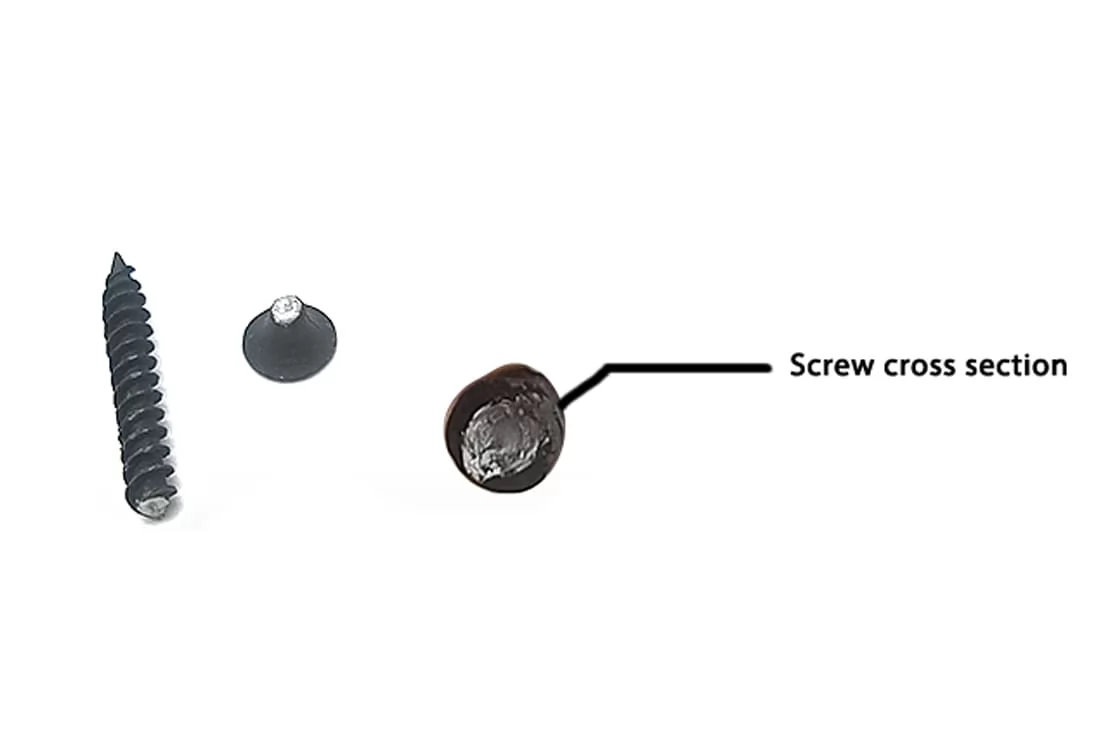

Brittle fracture of screws is a common problem in fastener manufacturing that can lead to significant financial losses. This issue occurs when screws break or crack easily during use, often due to the material's brittleness. For established factories, identifying the root cause of brittle fracture is essential to prevent scrapping entire batches of screws. In this article, we will explore the causes of screw brittle fractures, share our experience at Meigesi, and provide solutions to avoid this problem.

Screws are designed to withstand various stresses, but when they become brittle, they are prone to breaking. Several factors can contribute to the brittle fracture of screws, including the choice of raw materials, design flaws, and improper installation methods. Here, we explore these factors in more detail:

Raw Material Quality: The quality of the raw materials used in screw production is a leading cause of brittle fracture. Poor-quality materials, uneven hardness, or impurities can make screws more fragile and susceptible to cracking under stress.

Design Issues: Inadequate design can also contribute to screw brittleness. If stress concentration points are not reinforced, or if the pitch is too small or the thread profile is incorrect, the screw may not be able to handle the applied force.

Heat Treatment Problems: Incorrect heat treatment processes can lead to the formation of cracks or pores in the screws, further weakening them.

Improper Installation: Though not the primary cause, improper installation methods can exacerbate the problem. Over-tightening or using excessive force can cause the screw to fracture.

At Meigesi, we once faced an incident involving the brittle fracture of finished screws. After investigating the production process, we discovered the following:

Raw Material Quality: Upon examining the raw materials, we found that their quality was suboptimal, leading to uneven hardness and an increased likelihood of brittleness.

Design Review: We also reviewed the screw design but ruled out design flaws as the cause since the screw dimensions and thread profiles were within specifications.

Heat Treatment Process: A thorough inspection revealed no significant issues with the heat treatment process. We confirmed that there were no cracks or pores in the screws, ruling out heat treatment as the cause.

Installation Concerns: The possibility of improper installation was considered but quickly ruled out, as the fractures occurred in large batches, making it unlikely that installation was the primary factor.

After thorough investigation, we concluded that the raw materials used in production were the primary cause of the brittle fracture. This experience taught us valuable lessons, and we have since implemented several changes to improve our manufacturing process.

To prevent brittle fractures in screws, we recommend the following:

Select High-Quality Materials: Always use materials with higher toughness, such as medium carbon steel or alloy steel, which can improve the screw’s resistance to breakage.

Optimize Heat Treatment: Adjust heat treatment parameters to balance hardness and toughness, avoiding excessive brittleness that can lead to fractures.

Use Proper Installation Methods: Ensure screws are installed correctly. Avoid over-tightening or using excessive force during installation. For small or self-tapping screws, use an electric drill in short bursts rather than driving the screw in all at once.

Mechanical Straightening: For screws that are slightly bent, use mechanical straightening equipment to restore them to their original shape.

Heat Straightening: For more severely bent screws, heat them before straightening to reduce internal stress and avoid further brittleness.

Stress Tempering: Perform stress tempering on brittle screws to release internal stress and increase toughness.

Surface Treatment: Apply coatings or platings to improve the corrosion resistance and fatigue performance of screws, extending their lifespan.

Improved Design: Revise screw design to reinforce stress concentration points and adjust thread profiles or diameters to increase load-bearing capacity.

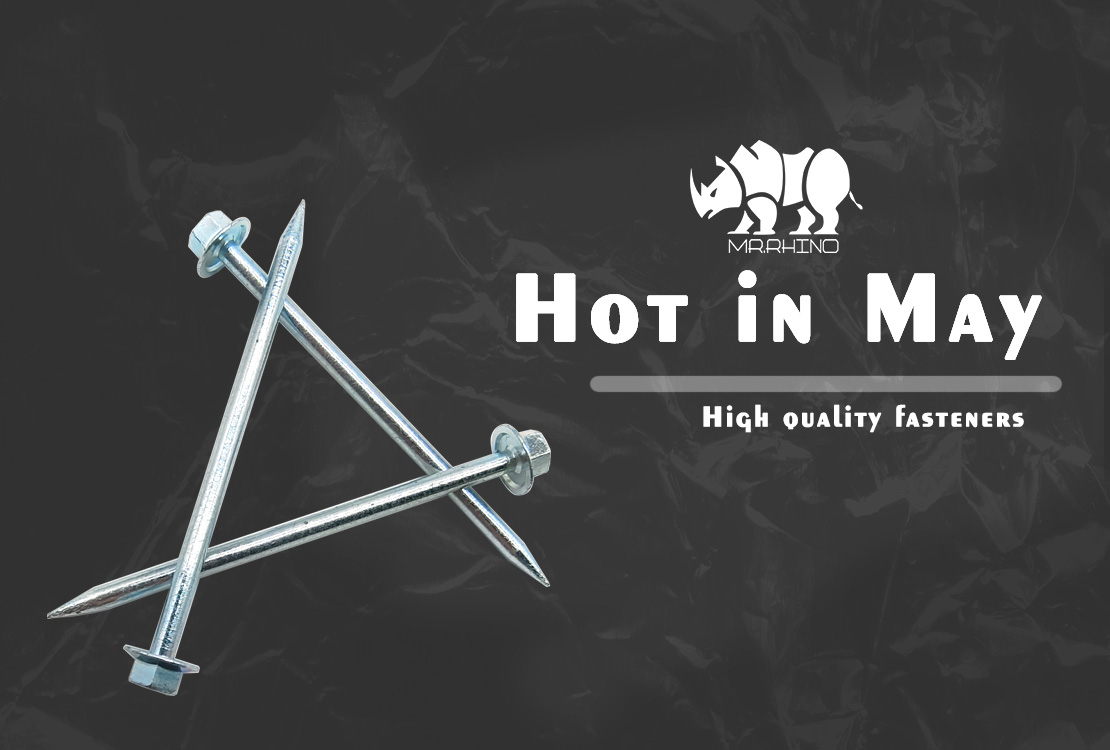

Founded in 2010, Yuyao Meigesi Fastener has been a leading manufacturer of fasteners, including screws, nuts, and bolts. With over 13 years of experience, we have built a solid reputation for delivering high-quality products to over 50 countries across Europe and South America. As a professional screw manufacturer, we focus on innovation, efficiency, and quality control to ensure that every screw we produce meets the highest standards.

If you're looking for reliable fastener products, we invite you to browse our product catalog or contact us directly to learn more.