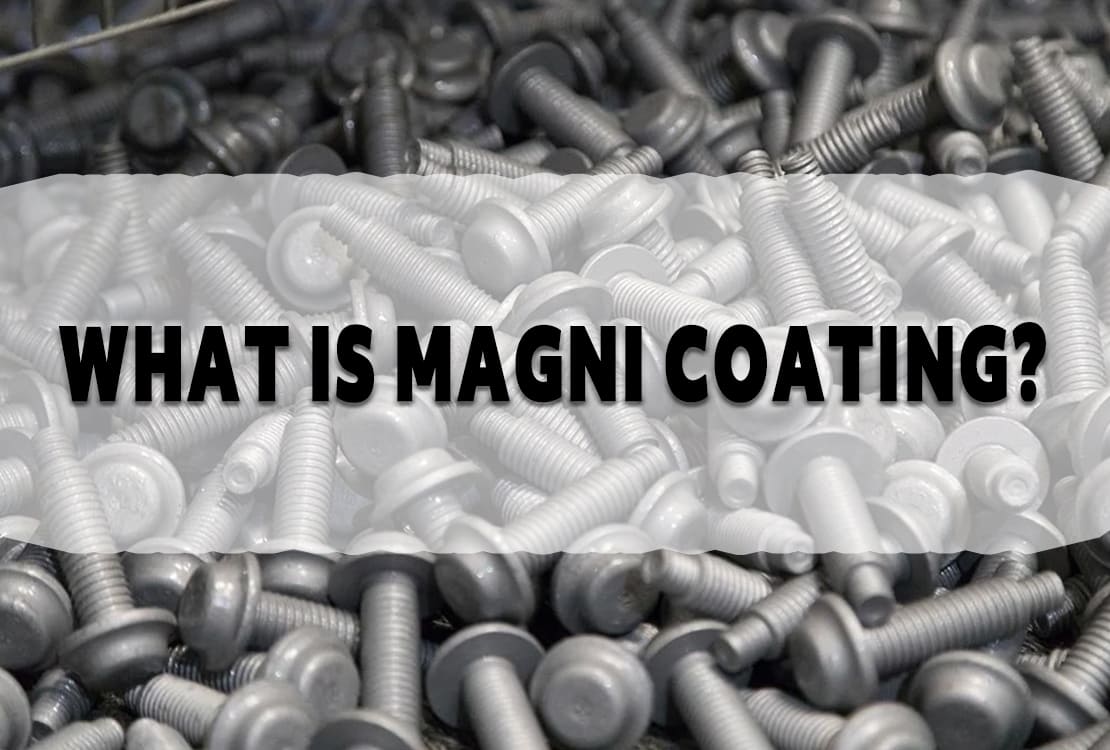

Magni Coating is a premier surface-treatment technology designed to significantly enhance the durability of metals, such as steel and aluminum. By applying a specialized engineered coating layer, it delivers superior corrosion resistance, rust prevention, acid-alkali protection, and optimized surface lubricity.

In the industry, "Magni Coating" typically refers to a robust dual-layer zinc-flake coating system:

This advanced system complies with high industry standards, including ASTM F3393 (Standard Specification for Zinc-Flake Coating Systems for Fasteners).

Based on industry performance data, Meigesi Fasteners highlights the following specific benefits of choosing Magni Coating for your components:

The synergy between the zinc-rich base layer and the organic topcoat creates a barrier that rivals traditional hot-dip galvanizing. Magni systems frequently exceed 720 to 1,500 hours in salt spray testing.

The organic topcoat offers exceptional resistance against acids, alkalis, automotive fluids, and solvents, making it ideal for harsh industrial environments.

Unlike hot-dip galvanizing, Magni Coating is a thin-film application. It is significantly lighter and maintains the dimensional integrity of parts, eliminating the need for thread re-machining.

As a non-electrolytic process, the Magni application method avoids the introduction of hydrogen into the metal. This makes it a safe and preferred choice for high-strength fasteners (Class 10.9 and above).

Magni systems are environmentally responsible. They are free from hexavalent chromium (Cr⁶⁺), lead, and cadmium, ensuring compliance with global regulations like RoHS and ELV (End of Life Vehicles).

The integrated lubricants in the topcoat provide consistent friction coefficients (torque-tension control), improving the speed and reliability of automated assembly lines.

The following table compares Magni Coating against other common industrial plating and coating methods, highlighting its superior performance in corrosion resistance and safety.

| Coating Type | Technology Type | Corrosion Resistance / Salt Spray | Hydrogen Embrittlement Risk |

|---|---|---|---|

| Magni Coating (Magni / Zinc-flake System) | Non-electrolytic zinc-flake coating with inorganic/organic topcoat (dual-layer system) |

High Often ≥ 720 h, up to 1000–1500 h depending on thickness. |

None Non-electrolytic; safe for high-strength fasteners. |

| Electro-zinc Plating | Electrolytic zinc deposition |

Moderate Suitable for indoor or mild environments. |

Present Requires post-baking to reduce hydrogen. |

| Hot-dip Galvanizing | Molten-zinc immersion coating |

Very High Excellent long-term protection for outdoor/structural use. |

None Melting process avoids hydrogen absorption. |

| Mechanical Plating / Galvanizing | Mechanical zinc powder impaction with abrasives |

Medium to Moderate Lower durability vs. hot-dip in aggressive environments. |

Very Low Mechanical process avoids hydrogen charging. |

| Ruspert Coating | Multi-layer coating: Zinc flakes + conversion layer + ceramic/organic topcoat |

High Strong protection from salt, moisture, acids, and chemicals. |

None Non-electrolytic system. |

| Dacromet / Zinc-flake Coating | Zinc-flake based non-electrolytic coating system |

Very High Up to 7–10× the performance of traditional zinc coatings. |

None Ideal for high-strength structural fasteners. |

| Coating Type | Application Suitability | Environmental Compliance | Typical Advantages / Ideal Uses |

|---|---|---|---|

| Magni Coating (Magni / Zinc-flake System) | Thin, uniform coating; excellent for fasteners and threads; customizable friction/color. | Chrome-free, low VOC, fully RoHS / ELV compliant. | Automotive fasteners, high-strength bolts, components requiring high corrosion resistance + dimensional control. |

| Electro-zinc Plating | Smooth surface, suitable for small hardware/threads. Limited for harsh environments. | Wastewater and heavy-metal concerns; stricter restrictions. | Indoor hardware and non-critical applications. |

| Hot-dip Galvanizing | Best for large structural components; may require thread re-machining due to thickness. | High zinc consumption but better performance than plating. | Outdoor structures, bridges, fencing, pipelines, heavy-duty components. |

| Mechanical Plating / Galvanizing | Suitable for small hardware; coverage may be uneven on threads/recesses. | No electro-waste; greener than electro-plating. | General hardware needing economical protection. |

| Ruspert Coating | Good for fasteners exposed to chemicals, seawater, concrete, etc. | Typically chrome-free, environmentally compliant. | Fasteners in harsh environments: construction, maritime, infrastructure. |

| Dacromet / Zinc-flake Coating | Excellent for automotive fasteners and parts with precise tolerances. | Chrome-free alternative widely used to replace electro-plating. | Automotive, industrial fasteners, structural components needing high durability. |

While Magni offers corrosion protection comparable to hot-dip galvanizing, it excels in specific engineering scenarios. It is the ideal surface treatment if your fasteners or metal components require:

At Meigesi Fasteners, we have integrated Magni Coating technology into our export product lines. It is widely adopted for our self-drilling hex washer head screws, ensuring long-term durability in demanding environments.

Over years of production, we have built solid experience and technical expertise in zinc-flake surface technologies. If you have specific requirements or questions about Magni coating solutions, please contact us. Our team is ready to provide the technical support you need.