As the Kingdom of Saudi Arabia (KSA) advances its ambitious Vision 2030, the construction and industrial sectors are undergoing a profound transformation. This national strategy aims to diversify the economy and reduce oil dependency through an investment of over $1 trillion in diverse engineering projects, positioning Saudi Arabia as the world's largest construction market.

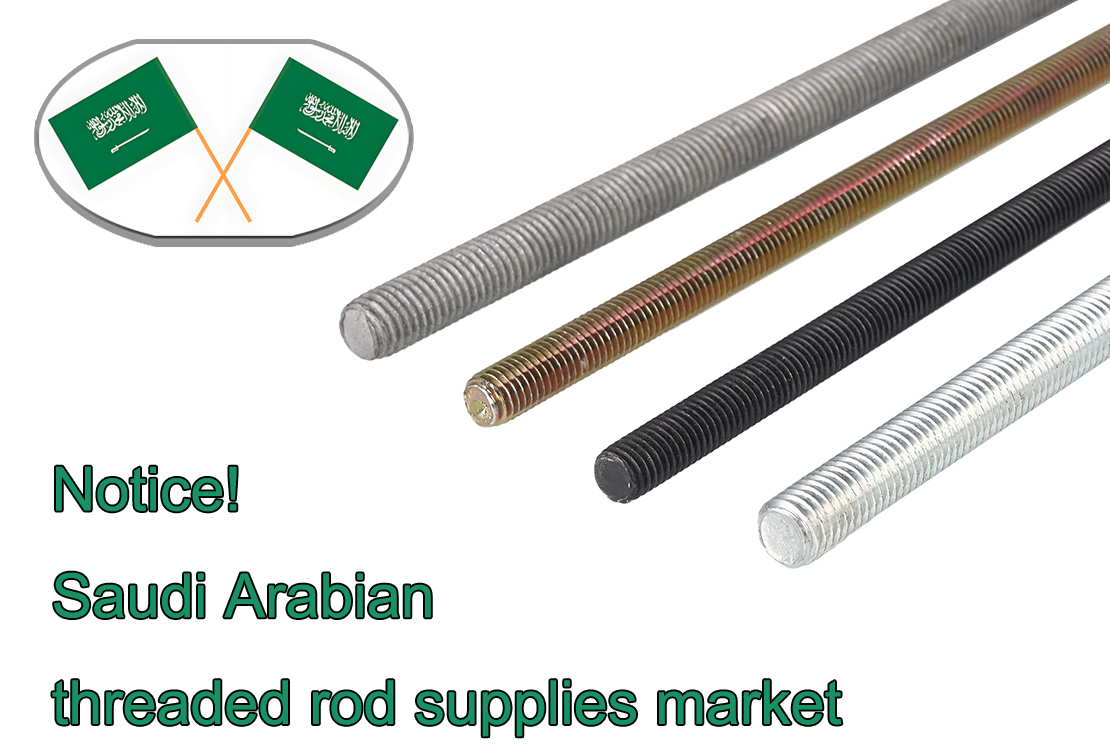

Within this expansive infrastructure landscape, threaded rods (also known as all-thread or continuous-thread rods) and their matching nuts serve as indispensable foundational components for structural connections, Mechanical, Electrical, and Plumbing (MEP) installations, and petrochemical equipment. Consequently, market demand is surging at an unprecedented rate. For manufacturers like Meigesi Fastener, which possess high-standard production capabilities and extensive export experience, the Saudi and broader Middle Eastern markets represent more than just high-volume consumption hubs; they are strategic arenas for realizing brand premium and aligning with global technical standards.

Saudi Arabia's "Vision 2030" is far more than an economic roadmap; it is a comprehensive revolution encompassing urbanization, energy transition, and industrial localization. This radical transformation has catalyzed an unprecedented surge in demand within the fastener industry, particularly for externally threaded rods. According to market research, the Saudi industrial fastener market is currently valued at $540 million. With the progression of "Giga-projects" such as NEOM and the Red Sea Project, it is projected that the market will require an additional 500 million units of fasteners annually.

Saudi Arabia is currently witnessing a peak in construction activities. A prime example is NEOM, whose centerpiece, "THE LINE," is a 170-kilometer linear city utilizing fully automated construction technologies and smart infrastructure. Such high-tech projects demand extreme levels of precision and consistency in fastener specifications. In these contexts, threaded rods play a critical role as fundamental components for structural beam-and-column connections, HVAC system suspension, telecommunications network support, and the anchoring of large-scale energy facilities.

Vision 2030 emphasizes the digital transformation of the construction industry, aiming to enhance execution efficiency through the integration of Building Information Modeling (BIM), Industry 4.0, and modular construction technologies. In this modernized environment, the degree of standardization for threaded rods and their matching nuts directly dictates the assembly speed of prefabricated modular components.

Meigesi Fastener's metric threaded rods, manufactured in strict accordance with DIN 975 or DIN 976 standards, offer exceptional versatility during on-site cutting and adjustment due to their continuous-thread design. This performance profile perfectly aligns with the rigorous efficiency requirements of contemporary construction methodologies.

As one of the flagship products of Meigesi Fastener, the threaded rod may possess a seemingly simple structure; however, within the rigorous engineering environments of Saudi Arabia, its material performance, thread tolerances, and mechanical indicators are the critical determinants of structural integrity and project safety.

The manufacturing of threaded rods involves a precision cold-rolling process. Throughout production, Meigesi Fastener maintains rigorous control over thread pitch and flank angles. In accordance with GB/T 192-2003 and its international equivalents, the thread profile of standard rods is designed as an equilateral triangle. This precision machining ensures smooth nut engagement.

| Thread Type | Specification | Key Feature |

|---|---|---|

| Coarse Threads | Large pitch, high strength | Suitable for wood or plastic materials, easy installation with balanced vibration resistance |

| Fine Threads | Small pitch | Suitable for precision metal connections, higher tensile strength and fine-tuning capability |

| Self-tapping | Self-forming within material | Simplifies construction steps, improves on-site efficiency for thin sheet metal |

| Trapezoidal | For power transmission and high-torque | Extremely high load-bearing capacity and low wear rate |

The high-end construction and heavy industrial sectors in Saudi Arabia demand fasteners with clearly defined strength classifications. Meigesi Fastener provides an extensive product portfolio ranging from standard carbon steel to ultra-high-strength alloy steels.

Characterized by moderate strength and exceptional cost-effectiveness. These are typically galvanized and widely utilized in interior finishing, general MEP hangers, and non-load-bearing structures.

These products undergo rigorous Quenching and Tempering (Q&T) heat treatments to achieve superior rigidity and tensile strength. They are the preferred choice for heavy machinery installation, steel bridge structures, and high-load architectural applications.

A specialized chromium-molybdenum (Cr-Mo) alloy steel engineered for high-temperature and high-pressure environments. This represents a flagship threaded rod offering from Meigesi Fastener, specifically tailored for the demanding requirements of the energy and petrochemical sectors.

The mechanical calculation models for these components typically adhere to the following formulas to determine the Safe Working Load (SWL) under specific environmental conditions:

In this model, fub represents the ultimate tensile strength of the material, As is the nominal stress area of the threaded section, and γM2 is the partial safety factor. Within the Saudi context—characterized by extreme thermal expansion—the selection of safety factors is typically more conservative to account for environmental stress.

The climate of Saudi Arabia is exceptionally hostile toward metallic materials. The coastal regions along the Red Sea and the Arabian Gulf are defined by high saline mist, relative humidity ranging from 50% to 100%, and ambient temperatures exceeding 50°C. These factors combined constitute some of the world's most severe corrosive environments, classified as Category CX/C5 under the ISO 9223 standard.

In the vicinity of the Saudi coastline, the deposition rate of airborne chlorides is exceptionally high. These salts combine with atmospheric moisture to form an electrolytic film within the thread roots of the rods, triggering severe pitting and crevice corrosion.

This is a critical concern particularly for austenitic stainless steels (such as Grade 304). Under the synergistic effect of high temperatures and chloride ions, materials that are otherwise corrosion-resistant can undergo sudden brittle failure. Consequently, for Saudi coastal projects, Meigesi Fastener typically recommends that clients upgrade to molybdenum-bearing Grade 316 stainless steel or adopt advanced coating technologies.

Extreme diurnal temperature fluctuations cause frequent thermal expansion and contraction in metallic threaded rods. This physical stress compromises traditional anti-rust oil films and accelerates the delamination or flaking of surface coatings.

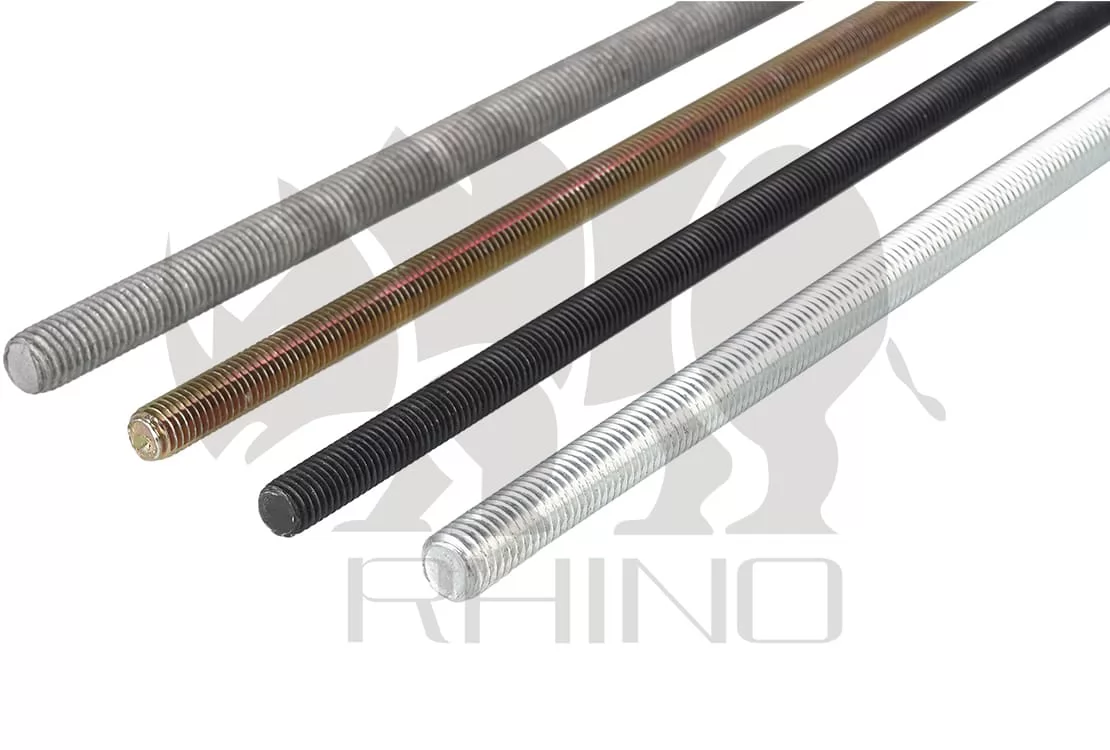

To mitigate the challenges outlined above, Meigesi Fastener utilizes a diverse portfolio of high-performance coatings applied to our threaded rods and matching nuts. These solutions are specifically engineered to provide long-term durability against the aggressive atmospheric conditions of the Middle East.

| Coating Type | Protection Principle | Salt Spray Test |

|---|---|---|

| HDG (Hot-Dip Galvanized) | Thick zinc-iron alloy layer for sacrificial protection | 500-1000 hours |

| Dacromet | Zinc-aluminum flake coatings, excellent high-temp corrosion resistance | High corrosion resistance, no hydrogen embrittlement risk |

| PTFE (Teflon) | Fluoropolymer layer, low friction coefficient, chemical inertness | 1500-2000 hours |

| Electroplating (Zinc-nickel) | Superior to traditional galvanizing, extremely high salt spray resistance | ≥1000 hours |

Fluoropolymer (PTFE) coated threaded rods are exceptionally popular in the Saudi market. These coatings serve a dual purpose: they effectively prevent "thread galling" and seizing due to corrosion, ensuring that nuts can be easily removed even after years of service in harsh environments. Furthermore, they provide high installation traceability through color-coding—for instance, the industry-standard blue coating is used to signify Grade B7 material, facilitating rapid identification on-site.

As a core pillar of Vision 2030, Saudi Arabia aims to generate 50% of its electricity from renewable sources by 2030, with 40 GW specifically designated for solar PV. Such large-scale photovoltaic arrays require tens of millions of fasteners to secure panel mounting structures.

In Saudi distributed rooftop solar projects, hanger bolts are the critical components connecting the roof structure to the aluminum mounting rails. Meigesi Fastener's SUS 304 stainless steel hanger bolts provide the following technical advantages:

In large-scale utility-grade power plants, C-channel strut support systems rely heavily on a combination of threaded rods and strut nuts (also known as spring nuts or channel nuts) for secure connections. Meigesi Fastener's fully threaded rods allow engineers to cut the rods to specific lengths on-site based on the topographic elevation differences. This adaptability significantly enhances installation efficiency in projects with complex or uneven terrain.

As a global energy titan, Saudi Arabia's energy infrastructure imposes nearly draconian quality requirements on fasteners. Major entities such as Saudi Aramco mandate in their procurement specifications that threaded rods must strictly adhere to the ASTM A193 Grade B7 standard, paired with ASTM A194 Grade 2H heavy hex nuts.

B7 threaded rods are manufactured from AISI 4140/4142 chromium-molybdenum alloy steel, engineered to meet a minimum tensile strength of 125,000 psi. In critical applications such as refinery heat exchangers, pressure vessels, and flange connections, these fasteners must maintain a constant clamping force (preload) in operating environments reaching up to 450°C.

Meigesi Fastener achieves superior performance through a meticulously controlled heat treatment process:

B7 threaded rods must be paired with high-performance nuts to ensure joint integrity. Meigesi Fastener provides Grade 2H heavy hex nuts, which feature a greater thickness and larger width across flats compared to standard hex nuts. This design provides a longer thread engagement length, allowing the assembly to withstand extreme preload levels without the risk of thread stripping or failure.

In a market traditionally partitioned among premier European brands (such as Hilti and Würth), American industrial leaders (such as Fastenal), and formidable local giants (such as Al-Rashed), Meigesi Fastener demonstrates a distinct competitive edge. This advantage is rooted in the deep integration of the Chinese supply chain coupled with the company's own robust technical heritage.

Compared to European suppliers, Meigesi Fastener leverages China's industrial clusters to realize the cost dividends of large-scale production, typically offering procurement costs 15% to 20% lower than equivalent European products.

Meigesi accommodates flexible Minimum Order Quantities (MOQ) and customized length requirements—a capability that is critical for Saudi Giga-projects, which are often in their early stages and subject to fluctuating design specifications.

Saudi wholesalers are increasingly pivoting toward direct procurement from Chinese manufacturers. Meigesi is capable of completing large-scale production and maritime delivery within a 30-day window, whereas local suppliers often face extended lead times due to capacity constraints.

Meigesi is actively exploring Industry 4.0 technologies, utilizing Internet of Things (IoT) sensors to monitor production line temperatures and torque levels. This ensures the metallurgical stability and consistency of every batch of threaded rods.

Through participation in international exhibitions such as "Big 5 Construct Saudi," Meigesi has established a technical service team intimately familiar with Arabian market regulations, providing Saudi clients with rapid quotations and technical consultations within 24 hours.

To facilitate reference for procurement officers across various Saudi industries, the following table summarizes Meigesi Fastener's top-selling products in the Middle Eastern market:

| Product Name | Size | Grade/Material | Application |

|---|---|---|---|

| DIN 975 Threaded Rod | M3 - M56 | 4.8 / 8.8 / 12.9 | Commercial building supports, MEP suspension systems, furniture manufacturing |

| B7 Double Ended Stud | M6 - M36 | ASTM A193 B7 | Petroleum refining flanges, high-pressure valve connections |

| B7 Threaded Rod | 1/4"-4" | B7 | Commercial building supports, MEP suspension systems, furniture manufacturing |

| Teflon B7 Threaded Rod | M6 - M36 | B7 | Commercial building supports, MEP suspension systems, furniture manufacturing |

| Stainless Steel Threaded Rod (A2/A4) | M6 - M30 | SUS 304 / SUS 316 | Coastal infrastructure, food processing equipment |

As a professional manufacturer specializing in fasteners for over a decade, Meigesi Fastener is committed to providing high-quality, cost-effective products and technical services to Saudi and global clients. We look forward to establishing a long-term, stable cooperative relationship with you and participating in the grand construction of Saudi Arabia's Vision 2030.